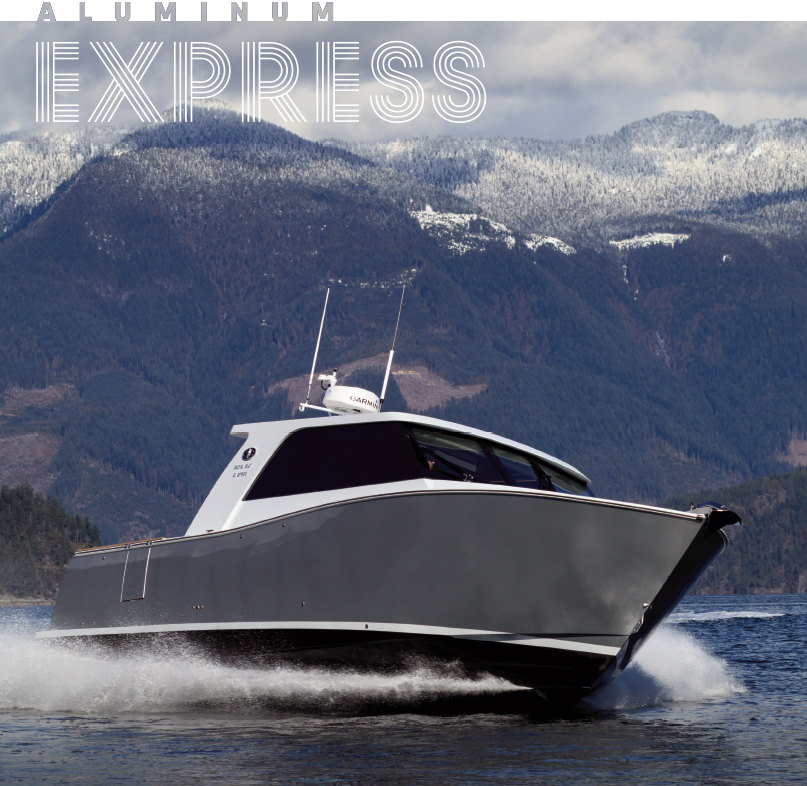

A silver and black boat appears on the horizon, leaving a white wake as it approaches. The shape is deceptive. From a distance, it’s hard to discern how big or small it is. The sleek, unadorned coupe gives no hint to its construction or origin. Deeply tinted windows seem flush with the boat’s clean, uninterrupted surfaces. No rails, chrome flourishes, or unnecessary details are to be seen.

A silver and black boat appears on the horizon, leaving a white wake as it approaches. The shape is deceptive. From a distance, it’s hard to discern how big or small it is. The sleek, unadorned coupe gives no hint to its construction or origin. Deeply tinted windows seem flush with the boat’s clean, uninterrupted surfaces. No rails, chrome flourishes, or unnecessary details are to be seen.

Whatever it is, this boat is moving fast. At 40 mph, it passes by in a silvery flash; nearly 40 feet from anchor to outboard. The hum of the twin outboards quickly fades as the boat speeds away. The only clue to its identity? Chrome script on the side that reads, “Coastal Craft 33 Express.”

Coastal Craft, based in the town of Gibsons on British Columbia’s Sunshine Coast, is best known as a manufacturer of durable and capable aluminum fishing boats, but it’s also a company always exploring new waters. After years of building larger and ever more consumer-friendly boats, the company made headlines in 2014 for building a series of 65’ luxury yachts. The aluminum yachts brought Coastal into the world of luxury boating to widespread applause. Now, the company is trying to create a hybrid of sport and luxury with that silver flash that sped by me—the 33 Express.

The key word here? Aluminum.

This material allows a boat to be both strong and lightweight, plus aluminum resists corrosion so it functions well both in salt and fresh water. By selecting aluminum as a main building material, Coastal Craft is free from the constraints of fiberglass molds. The company has taken advantage of this flexibility and is known for innovation along with a reputation for impeccable fit and finish. Those winning qualities are embedded in the 33 Express, which came out of the factory in late 2019 and debut at the Seattle Boat Show in January 2020. It was there that I overheard boaters saying, “Is that really made of aluminum?” and “Wow, that’s gonna be a star in Miami.”

That’s exactly the response Coastal Craft’s founder and President Jeff Rhodes wanted. The Coastal Craft team created the stylish design for new markets like California and South Florida. Coastal leveraged its expertise to maximum effect both in design and performance with this build.

Below the gunwale, the Express shares a great deal with another relatively new Coastal Craft boat – the 33 ProFish, introduced in 2018. Above it, however, the 33 Express is characterized by a radically different cabin with an emphasis on style and luxury. The Express is only fractionally wider than its ProFish sister overall, but the cabin is considerably wider within the hull’s footprint. That’s specifically to give it a large, airy salon and a big back deck. A huge sunroof sits up top, offering the option of boating al fresco but providing a sealed top in sunny Miami or rainy Seattle.

The salon’s glass doors open to an expansive aft deck. Coastal’s core customers are fishing people and the 33 Express is adept at fishing; but the emphasis is on functional luxury both inside and out.

“We were looking to give boaters a different kind of platform,” Rhodes says, “something which had fishing amenities, but also something designed to be a social space.” On this boat, the stereo equipment and fine interior fittings are as important as rod holders and bait boxes.

The slick exterior is a result of cloaking all that entertaining space in a creative way. “We were aiming for a really clean and crisp look while maintaining functionality,” Rhodes adds.

The flush glass, swept back windshield, and clean lines give the boat a distinctive 21st-century look and would be just at home in Biscayne Bay or Newport Beach as in the fjords of Howe Sound. Like an Arc’teryx® jacket (another British Columbia favorite), it’s stylish and comfortable but gives away nothing in functionality.

According to Rhodes, customers already want more of these boats. A 41-foot variation of the Express is due in 2021, but first, here’s our look at the 33 Express.

“Sometimes at a show, a customer will notice that we’ve put a box or a handle or a feature in a particularly convenient place and ask us how we thought of it,” says Coastal Craft Operations Manager Jason Dugal. “Usually, it’s because somebody asked for it and it worked, so we made it available for everyone.”

No two aluminum boats are exactly alike because they are assembled in a jig from sheet aluminum alloy, and Coastal Craft allows a high degree of customization on each boat. But the company doesn’t make one-offs. Instead, it applies lessons learned in each build to all the boats built after that. Simply put, it’s “kaizen,” the Japanese term for continuous improvement, that’s at work on every single build.

“When we say we allow customization,” Dugal adds, “We really do.” By keeping certain structural and basic elements the same, the boat can be tailored without adding too much extra cost or complexity. Additional features can also be adopted by modifying the boat even after it’s built. On my visit to the factory, two boats were being modified, and the lessons learned will be applied to future builds.

The company gets a great deal of feedback (and sometimes visits) from its owners. “We always have a spot for them at Gibsons Marina,” Dugal says. No sooner did the words come out of his mouth, than he pauses and smiles, “Now that I said that, I know I’m going to have a day where seven boats show up at once.”

Feedback from customers who were more interested in cruising than fishing prompted Jeff Rhodes to conceive of the 33 Express. “Most people were suggesting that 80 percent of the time they wanted

the big salon and the big back deck,” he adds, “and were willing to compromise on accommodations. They wanted to have more people on board and more usable space for them.” For those reasons, the salon dominates the hull, with a six-and-a-half foot berth at the front. “Having now built two and shown them extensively, most customers respond that the salon feels more like a 40- or 45-footer than a 33,” he adds.

It does feel big, and the huge glass area and sunroof belie its actual size. I sampled Hull #2, built for Floridian sunshine with tinted windows. “The boat is ideal for a couple’s cruiser or a small family,” Rhodes says, “and in markets like Florida and California, there’s less overnighting than in the Pacific Northwest.” You could still do overnight trips with friends and family, as the dining space converts into a second berth if needed, and optional fuel tanks and a generator (inherited from the ProFish) can take you out very far. Rhodes, however, sees the Express primarily as a day-and-night entertainer rather than a distance cruiser.

Although the interior structure is derived from the ProFish, there’s more of a luxury emphasis inside the Express. Beautifully finished black walnut cabinetry and paneling dominate, with storage in every conceivable spot with push-button handles. The glassy expanses are framed by long accent lights that brighten the interior.

“The Express interior is essentially a scaled-down version of our 65 interiors,” says Coastal Craft Joinery Manager Tyler McMullen. “Same fit and finish, same accents and details, just simplified and more compact.” Even boaters just over six feet tall won’t be cramped in the Express’ confines. The berth up front is modest, but the sloped sides of the front of the hull add some room and convenience.

Space in the galley is well organized and comprehensive. Owners can choose their own setup, but everything is within easy reach. After a day out fishing, you could easily fry up a couple of salmon fillets and a side dish on the Force 10 electric range without having to contort yourself or interrupt your passengers while they play rummy at the dining table.

The head is simple and reasonably large for a boat of this size. A shower is optional, but given the boat’s mission, Rhodes expects few will be spec’d out in that way. The non-shower head is also finished in dark walnut with the same high-quality joinery as the rest of the interior.

“We’re really in love with that dark walnut,” says McMullen, “It’s a very rich finish and lightweight. To keep overall weight down, lightening holes are drilled in places customers cannot see, that keeps efficiency up but doesn’t affect quality. Joinery doesn’t end at woodwork either,” he adds, “because aluminum varies with welding, the flush exterior windows were also a challenge. Ordering and fitting the glass requires very precise measurements and tolerances.”

From any real distance, say 5 feet or more, the entire window setup looks like one sheet of uninterrupted glass. The design could easily have come from the pen of iPhone designer Jony Ive.

After my tour of the factory and a detailed look at the 33 Express’s interior, it was time for the main event—a ride on the speedster. Dugal, McMullen, and I set out aboard Hull #2 from Gibsons Marina. Joystick control is a frequently chosen option, but Hull #2 only has throttle controls. We backed away slowly from the dock crowded with boats and calmly moved out into Shoal Channel.

As it was weekday, and a cold one at that, we had the water pretty much to ourselves aside from a few barges and a lonely old tug-and-barge pair cleaning up stray lumber near the New Brighton public dock. Howe Sound and Gibsons became famous throughout Canada in the 1970s and 1980s, thanks to the long-running TV show The Beachcombers. The show followed the misadventures of Greek-Canadian log salvager Nick Adonidas (played by actor Bruno Gerussi) and his tug Persephone as they kept coastline free of stray lumber.

Then, as now, there’s plenty of debris that breaks away from the log booms moving down from the giant lumber and pulp operations at Port Mellon. With our eyes peeled, we gradually picked up speed past Keats Island and then Gambier Island. One of the advantages of an aluminum boat is durability, and Coastal Craft’s aluminum structures are not an exception. If you hit a deadhead at 35 knots, for example, it may hurt your paint but you won’t sink.

All Coastal Crafts sport lightweight planing hulls, and by extension, the Express is very fast. It has a quoted top speed of 41 knots, but in clean water you’d hardly know how fast you were moving unless you were watching the instruments. It might be different in nasty chop, but the shallow draft (just 2 feet) and modest deadrise give the boat a smooth ride and ski-boat agility. “It’s a ton of fun being able to make tight turns at 40 mph,” Dugal says. The boat corners quickly indeed, but it feels stable.

Two optional gas-powered Mercury Marine Verado 400s push the boat to the tune of 800 horsepower. They’re ethanol-friendly, too. “The standard engines are the Verado 350, but you can option up or option down,” says Rhodes.

The company began switching its designs to outboards a few years ago in part to offer more space on their boats, and because outboard technology became more reliable and efficient. The twin engines return good fuel economy in the Express: One nautical mile per gallon at 30 knots, depending on the water and your disposition to winding it up.

None of this action detracts from the soft confines of the boat. It’s not hard to imagine bombing around the San Juan or Discovery Islands all day without feeling worn out. The cabin is well insulated with thick layers of sound deadener, and as you’d expect from a boat built for entertainment and social time, it’s easy to converse at full speed. Even with the sunroof open, you can have a conversation without raising your voice.

At the time we were on board, Hull #2 had no rails installed. This offers the visual experience in entirely unadulterated form, but you have to be careful putting out your fenders. “When we built that hull, we were fairly sure it would be sold to a customer in South Florida,” says Jeff, who explains that there’s a bit of a bias against rails in Florida. “Rails can be distracting with the glare, and there’s also an aesthetic preference.” At the very least, he suspects many owners will fit at least a top rail to grab on to when heading to the bow.

Out back, Hull #2 also differs from Hull #1 in that the deck is set up with a bent towards recreational fishing. “It isn’t exactly set up as we’d see in the Pacific Northwest for salmon or bottom fishing, though it’s certainly functional for those. We also wanted to make a good setup for warm water fishing and high-speed trolling,” Rhodes says.

Hull #1, in the meantime, has a full rail setup with a large seating and picnic area on the back deck. The upholstery is color-coded to match its pale-blue topsides. Both setups feature two watertight doors to the outside world; one on the side of the boat and one onto the back near the swim step. The back deck is full of lockable panels for everything from bait to fenders to large pieces of luggage. On the ProFish, these spaces are often set up for fish lockers. Dugal says, “We found that more often than not, customers were hauling stuff rather than fish. Lots of people want that utility.”

Rhodes says the 33 Express has received a strong positive response from customers thus far. The first two hulls are already spoken for, with a third about to begin construction. Fully outfitted, the Express 33 tops $700,000, but there’s no shortage of demand. Coastal Craft’s delivery slots are booked until August of 2021. That in mind, the company is readying a larger, more luxurious version.

The 41 Traditional (closer to the ProFish) and 41 Express versions will debut early next year, and they’ll feature more of everything customers liked about the 33s. For the 41’ Express, which will be 41’ long at the waterline and carry a 14’ beam, allowing for a significant upgrade in accommodation space. The new boat will preserve the basic style of the 33 Express, but include a fully-enclosed berth on the port side below the dining area and a larger master stateroom. The roof will be a little taller, but the sporty proportions should stay about the same as the 33.

“We’re getting a lot of comments at shows about how spacious the 33 Express is, and what a comfortable feeling the salon and back deck provide,” says Rhodes. McMullen also notes that some customers have walked up and tapped on the boat’s sides, then give him a quizzical look. “Is that really aluminum?” they ask. “It really does look and feel quite different from anything in that size range,” says Rhodes. Having tried the Express 33, I would agree. When the next size up becomes available, I’ll be back for a look at the latest Coastal Craft.

THE FACTORY

CRAFTING ON THE SUNSHINE COAST

Since 1996, Coastal Craft has delivered more than 140 of its aluminum boats to customers across Canada and the Unites States. In the company’s early years, it specialized in work boats for logging, rescue, and whale watching operations. In 2001, a customer requested one of those boats be outfitted belowdecks with creature comforts such as a sleeping area and a head. So it was then that Coastal’s modern line took shape, eventually leading to the firm’s 65’ luxury yachts in 2014. At the beginning and now, Coastal builds according to the customer’s wants and needs.

Coastal Craft produces all its boats and most of the components in a facility in upper Gibsons, British Columbia. About 35 employees hum away welding, painting, producing wood fixtures, and assembling. The bucolic location, about two miles from Gibsons Marina, offers a high standard of living for the employees with lower overhead costs than in nearby Vancouver.

Each hull starts out as sheets of aluminum which are MIG (Metal Inert Gas) welded into shape, and the structure formed in a massive jig. Once the boat is structurally complete, it moves into the paint booth, and finally to the outfitting area. Between these steps, individual components are assembled in a modular way by small teams. The woodshop hums with the sound of machines and sanding. Everything from electronics panels to instruments are assembled with meticulous care.

Components are then installed in an approach that saves time and supports quality control. The build process is a model of efficiency, informed by Toyota’s famous “just in time” and team-oriented methods of production. Teamwork in action is easy to observe in Coastal Craft’s facility because the process is so refined and the individual teams – usually no more than five people – so organized. At any given time, six boats may be in various stages of production.

Case in point? We boarded a 33’ ProFish in the outfitting area at 9:40 am when it had no instruments or ceiling panels. Only the structure of the galley was assembled. By 2:30 pm, the ceiling soffits, galley countertop, and some of the helm instruments were carefully crafted and put in place.

Many customers also bring their boats back for service and modification after delivery. Because the hulls are aluminum, a great deal of extra customization can be done later. While I was there, one boat was in the outfitting area was getting an extended deck roof and a watertight side door added to the hull. The current outfitting area was built for the construction of the big 65s, but now houses two bays where smaller boats can be in process simultaneously.