The Francis Lee story is part love of craft and part love of sailing. The combination is simply the best of sailing and a showcase for the Pacific Northwest’s boatbuilding skills. (see complete list at end of article of those who contributed)

Love of Craft

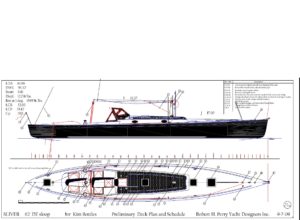

It’s hard to find someone with greater love of craft that naval architect Bob Perry. At age 67 he continues to come up with elegant solutions for wide ranging clients. These particular clients, Kim and Susan Bottles, were already long time friends, which made the experience that much richer.

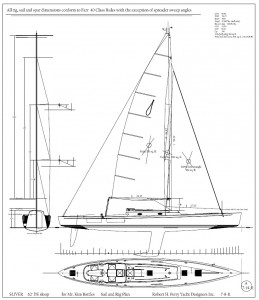

Perry and the Bottles shared an affinity for Bill Garden’s Oceanus design, which led to a close study of L. Francis Herreshoff’s drawings of the “Ultimate Sailing Machine.” The path started becoming clear, though Perry said “You want long waterline, I can do long waterline. But it will be mine, not his.” And so started the 4-year process that ended in January’s launch of the Francis Lee.

This was, from nearly the outset, to be a Pacific Northwest project to showcase the region’s boatbuilding expertise and give a shot in the arm to the local marine industry.  But it became much more than that when the Northwest School of Wooden Boat Building was chosen for the construction. The School’s enthusiasm for the project spread and soon just about every skill and talent necessary to create this vessel came together around gthe boat.

But it became much more than that when the Northwest School of Wooden Boat Building was chosen for the construction. The School’s enthusiasm for the project spread and soon just about every skill and talent necessary to create this vessel came together around gthe boat.

Tim Nolan and Jim Franken, along with Russell Brown and Brandon Davis, were convincing the boat should be of wood composite. That was fine with Perry, who of course wanted keep the boat light, though he had initial reservations. “I was very nervous about the trip planked hull,” Bob explained. “I wanted all carbon fiber. I was concerned about weight. But I had a pretty good weight study started and when we plugged the numbers in for the strip planked hull it looked doable. But I was still concerned, skeptical. But the first time we weighed the hull I was very pleasantly surprised. It looked like we would hit our weight target. That has proven to be the case.”

Hull construction was a Western Red Cedar core sheathed in Triaxel VectorPly eGlass set in West System Epoxy. The cabin/deck/cockpit was built as one piece, as first suggested by Tom George, a Port Townsend boat builder. Foam core composite was utilized for all of the structural interior pieces.

Hull construction was a Western Red Cedar core sheathed in Triaxel VectorPly eGlass set in West System Epoxy. The cabin/deck/cockpit was built as one piece, as first suggested by Tom George, a Port Townsend boat builder. Foam core composite was utilized for all of the structural interior pieces.

And while Perry drew the striking lines, he had a lot of help behind the scenes from Franken in the aftermath of Perry’s son Spike’s death. “Jim stepped up and calmly worked to get the 3D model of the hull accurate to my drawings. Jim is one of those guys whose efforts are hidden, but critical,” Perry said.

And while Perry drew the striking lines, he had a lot of help behind the scenes from Franken in the aftermath of Perry’s son Spike’s death. “Jim stepped up and calmly worked to get the 3D model of the hull accurate to my drawings. Jim is one of those guys whose efforts are hidden, but critical,” Perry said.

A couple of important pieces were used at tremendous cost savings. Bob Pistay suggested a carbon Farr 40 rig had nearly the identical proportions as what Perry had drawn, and sure enough Bob Perry agreed it would work. A used one was available. A gorgeous carbon fiber rudder, virtually unused from Bob Perry’s Free Range Chicken project, was basically a perfect fit for Francis Lee.

A couple of important pieces were used at tremendous cost savings. Bob Pistay suggested a carbon Farr 40 rig had nearly the identical proportions as what Perry had drawn, and sure enough Bob Perry agreed it would work. A used one was available. A gorgeous carbon fiber rudder, virtually unused from Bob Perry’s Free Range Chicken project, was basically a perfect fit for Francis Lee.

Love of Sailing

Francis Lee is named after Kim’s father, who helped foster a love of sailing in the family, and a love of simple, good sailing wooden sailboats. He owned a Sea Bird yawl, a Folkboat and International Dragon. His son carried on the sailing tradition with a series of boats built in a variety of styles and materials.

This boat is really the distillation of a long family sailing history. A bit of Bruce King’s Nantucket Splinter, Herreshoff’s Rozinante and Istalana C. Raymond Hunt’s 210, Joel White’s Sakonnet 23, Ben Seaborn’s Twinkle and Alex Irving’s Sparkle are all in Francis Lee. But there’s clearly a lot of Knud Reimer’s Metre boats and a whole lot of Oceanus.

Francis Lee is simple and elegant, from bow to stern a product of the Pacific Northwest. Francis Lee the sailor would be proud.

Francis Lee is simple and elegant, from bow to stern a product of the Pacific Northwest. Francis Lee the sailor would be proud.

Note: Bob Perry has a blog post on the boat here, and there is an extensive discussion of the design and build on Sailing Anarchy.

Note: Bob Perry has a blog post on the boat here, and there is an extensive discussion of the design and build on Sailing Anarchy.

The Crew on the Sliver Project

Bob Perry – Robert H. Perry Yacht Design

Bruce Blatchley – Instructor NW School of Wooden Boatbuilding

Tim Nolan – Structural Engineering

Jim Franken – CAD Lofting and Project Management

Russell Brown – PT Watercraft Lamination Consultant and Project Management

Brandon Davis – Turn Point Design CNC Machining and Composite Panels

Carter Conklin – Turn Point Design CNC Machining and Composite Panels

Bill Campbell – Custom Metal Fabrication (Keel Floors)

David Means – Pacific Fisherman Keel Fin Fabrication

Scott Graham – Non Ferrous Metals Ballast Bulb

Tim Ryan – CSR Marine Paint and Assembly (Plus all of the Crew at CSR)

Jordan Primus – Shipwright

Fred Shwiller – Shipwright

Amos Howe – Shipwright

Cooper Parish – Shipwright

Kai Lorenz – Shipwright

Troy Craig – Shipwright

Ivan Erdevicki – Preliminary Engineering

Erik Bentzen – Surveyor

Frank & Axel Schattauer – Sailmakers

Derek & Brent Bottles – Collaborators

Students who Worked on the Project

Jack Arrington

Kevin Bloomfield

Troy Craig

Sheridan Crawford

Tara DeGraff

Christopher Erickson

Chris Gilda

Charlie Givens

John Godbois

Daniel Heineman

Amos Howe

Randy Labrune

Simon Lisiecki

Kai Lorenz

John Nowak

Cooper Parish

Jordan Primus

James Saint George

Fred Shwiller

Justin Taylor

Kyle Tierney

Brett Townsend

Simon Webb

Reid Wilburn

Reece Ziomek

Others who gave me advice, ideas or other help directly or indirectly

WLYDO

Meade Gougeon

Tim O’Connell

Scott Rohrer

Dick Pratt

Tom George

Bruce Hedrick

Jonathan McKee

Neil Rabinowitz

Russell DeLombard

Tina Gilbert

Bruce McPherson

Lynn Bowser

Bob Pistay

Paul Jenkins

Justin Kelleher

Rob Vaughn

L. Francis Herreshoff

Bill Garden

Knud Reimers

C. Raymond Hunt

Ben Seaborn

Alex Irving

Bruce King

Joel White

Paul Zeusche

(If I have forgotten someone please let me know so they can be added to the list.)

3 comments

I neglected to mention the WLYDO and Tim O’Connell for their part in the project.

Kim

How could I ever have forgotten to add Frank & Axel Schattauer my sailmakers to the list? I guess I am getting old and senile.

Congratulations Kim.